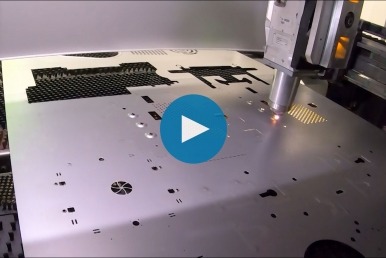

Strippit PX-L: the machine that punches, forms, bends, taps and laser cuts

An increasing number of sheet metal parts required in manufacturing nowadays can benefit from combining the processes of laser cutting, punching, tapping, forming and bending. Examples include computer chassis, electronics housings, lighting equipment components, industrial machines for the food industry, HVAC components, and a wide variety of specially designed parts. An extremely flexible machine is needed for workshops to be able to serve this growing but demanding market.

How about having one machine that can do all of these operations in one process?

The ultimate value adding machine! Laser, Punch, Form, Tap and Bend in one

Meet LVD’s Strippit PX-L. It’s a Combination of all processes in one. It can laser cut, punch, form and tap sheet metal parts as well as bend them up to 75 mm high adding the most value to your parts in one process.

If you are serving this market of complex metal parts or want to enter it, Strippit PX-L is your solution of choice. Programming is easy with LVD’s CADMAN® software, which allows operators to program the machine with just a few clicks, using the part’s 3D drawing as input.

Strippit PX-L adds up to 75% more value to your parts in one machine compared to conventional processes